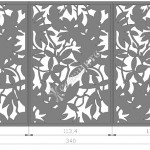

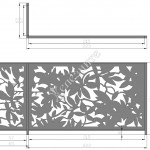

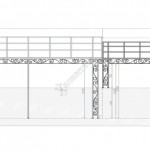

The initial task of inventing and making wrought iron sheds in front of the entrance of a house and a garage in a suburb of the capital seemed to us difficult to achieve and almost impossible. The difficulty came from the fact that the two sheds had to fit together in form and form a single shed that at the same time had good drainage, could withstand snow, wind, etc. After much thought and design, the idea was arrived at to make two gabled roofs, connected to each other with u-shaped brackets and a gutter for the drainage in the middle. We borrowed the forged elements on the trusses and friezes from details of the existing doors and fence. The assembly process of wrought iron sheds was also not an easy task, as evidenced by some of the following photos:

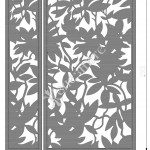

The end result: A shed made of wrought iron, with hand-forged elements in black. The aging is a copper patina and the finish is a solid polycarbonate bronze that perfectly imitates glass.

The end result: A shed made of wrought iron, with hand-forged elements in black. The aging is a copper patina and the finish is a solid polycarbonate bronze that perfectly imitates glass.